| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : SHARE FILTERS

Model Number : SG-FD-NF-03

Certification : Reach Svhc, SGS RoHS, California Proposition 65

Place of Origin : Zhejiang, China

MOQ : 200 m2

Price : $1 for 500 m2, $0.9 for 1,000 m2, $0.7 for 5, 000 m2

Payment Terms : L/C, T/T, Paypal

Supply Ability : 1, 0000 m2 / day

Delivery Time : 5 working days

Packaging Details : PE bag and carton

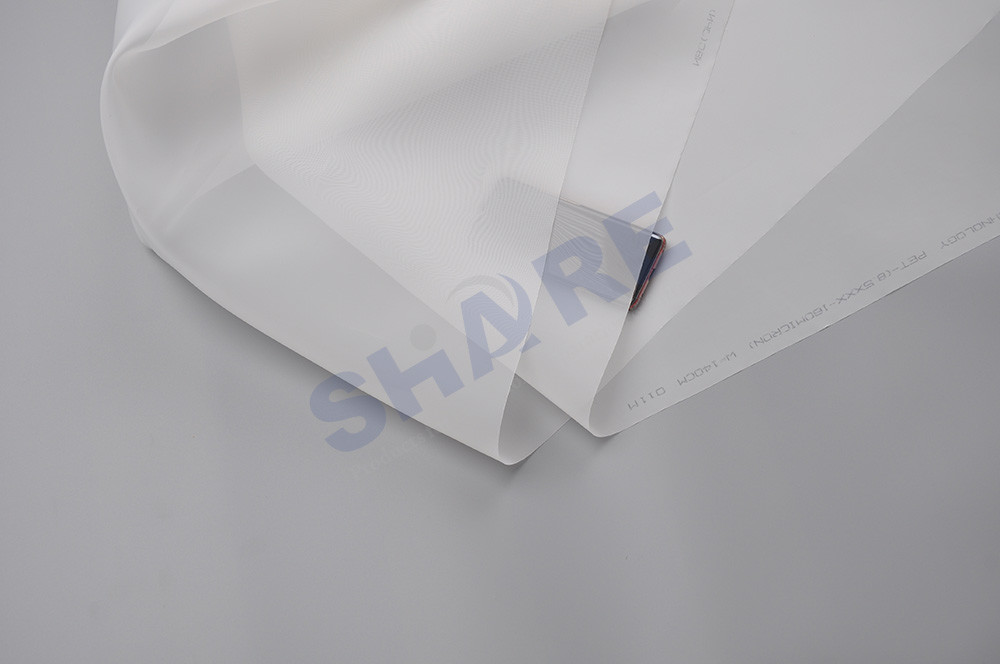

Material : 100% Nylon Monofilament Mesh

Item Number : 6xxx-17xxx

Mesh Opening : 213-81 Microns

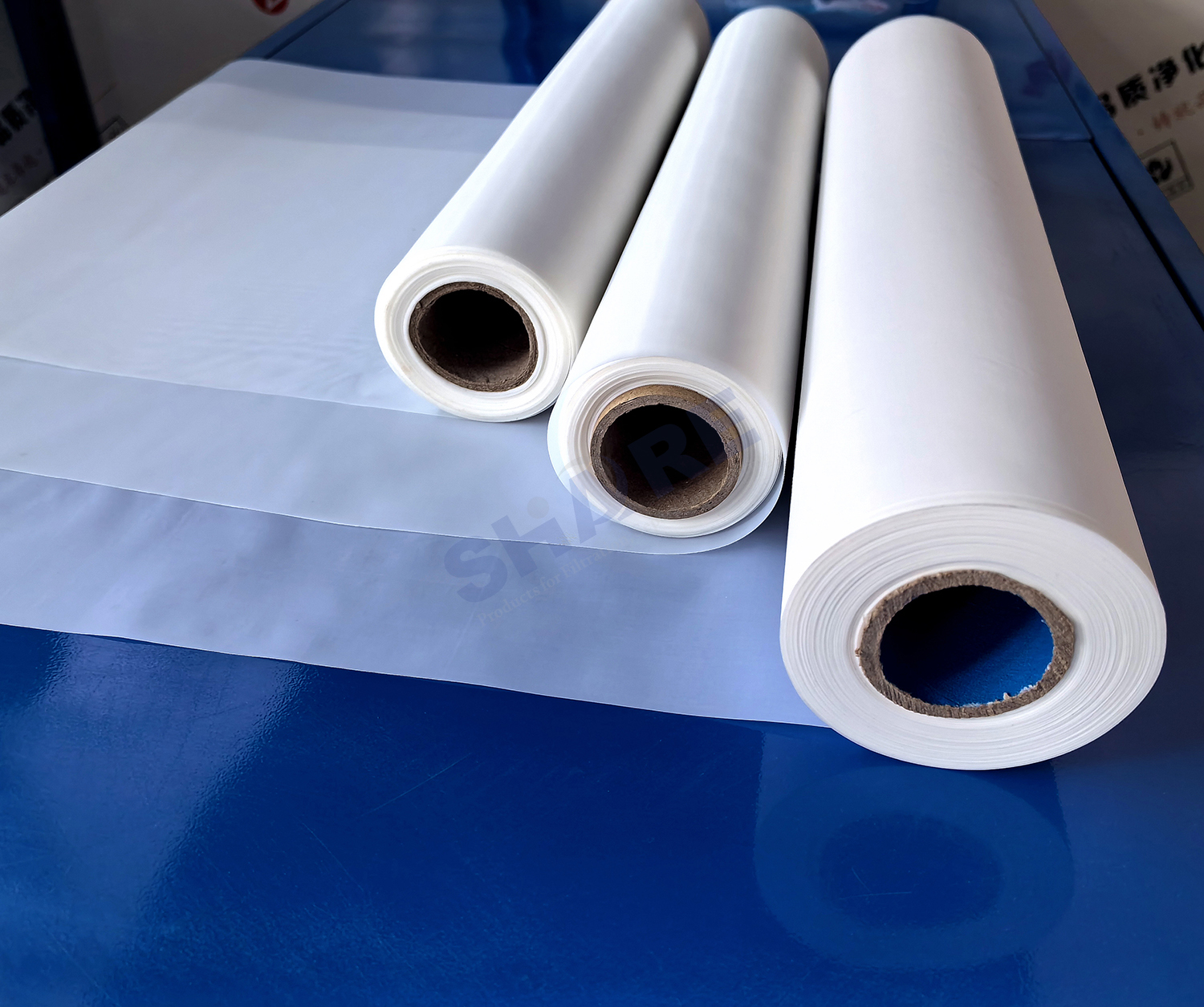

Roll Length : 30-70m/roll

Application : Centrifugal Sifter

PA-XXX fabric are used for harder types of wheat and durum. It's the highest strength mesh in the flour sieve mesh series. The aperture size is down due to the thick thread. It' s used in production line of soft and hard wheat flour. It has longer life for this kind of reinforced mesh.

Descriptions

Flour milling mesh commonly are nylon material because nylon offers superior wear resistance compared to polyester.

SHARE nylon flour milling mesh is special designed for milling industry, such as flour milling, corn milling and other grains milling.

Our nylon flour milling mesh consists of PA-GG series, PA-XX series and PA-XXX series.

PA-XX series flour mesh is the most commonly used in the flour milling.This type of flour mesh is constructed using both monofilament and double filament, the interweave double filament make the mesh surface much more coarse and therefore improve the screening effect. XX series screening milling mesh is a kind of auxiliary screening material specially used in food screening and flour milling industry in the powder cleaning and fine grinding stage.

PA-GG series flour mesh is mainly used in the coarse screening and peeling screening. PA-GG flour mesh is with high elasticity and can replace stainless steel mesh. GG series flour milling screening mesh is a kind of auxiliary screening material specially used in food screening and rough grinding stage of flour industry.

PA-XXX series has the highest tension among nylon flour mesh. It is woven with the thicker threads to reduce the open area, which make it has a longer service life. XXX series screening milling mesh is a kind of auxiliary screening material specially used in food screening and flour making industry in the powder cleaning and fine grinding stage.-

| Sifting Fabrics | Machines | Area of use | Main benefit | Standard use for | ||

| Sifters | Centrifugal Sifters | Purifiers | ||||

| PA-GG | × | × | Coarse sifter covers | Anti-abrasive qualities | Coarse sieves | |

| PA-Milling | × | Soft wheat, biscuit and rye flour | High efficiency | Flour sieves | ||

| PA-Milling Forte (MF) | × | Good lifetime and efficiency | ||||

| PA-XX | × | × | Soft wheat, biscuit and rye flour | Long lifetime, high efficiency | ||

| PA-XXX | × | Durum and hard wheat flour | Strongest fabric | Centrifugal sifter | ||

| PET-GG | × | Purifier covers | Constant tension | Purifier | ||

| Product name | PA-XXX Series Nylon PA6 Flour Milling Mesh 6XXX to 17XXX |

| Manufacturer | Taizhou Share Filters Co. Ltd. |

| Brand | SHARE FILTERS |

| Material | Food grade nylon PA6 |

| Color | Natural |

| Weave type | Plain weave |

| Common width | 110cm, 127cm, 136cm, 158cm or customized |

| Roll length | 30-100 meters or customized |

| Micron size | 213um to 81um |

| Certificate | ISO19001 SGS ROHS REACH |

| Samples availability | 1 meter free |

| Advantages | Thicker fabric Uniform and stable meshes Strong and efficient filter result Food grade materials Complete specifications High efficiency |

| Application | Food processing screening filter Plansifter in flour milling Single and double bin flat screen Aluminium alloy screen Grinder screen Powder cleaner screen Vibration screen Sieve bone Press filter cloth Starch filter cloth And many more |

Technical Datasheet

| Precision Nylon Flour Mesh Specifications | |||||||

| Fabric Number | Mesh Count | Thread Diameter | Mesh Opening | Open Area | Mesh Thickness | Weight | |

| n/cm | n/inch | μm | μm | % | μm | g/m2 | |

| PA-6XXX | 30 | 76 | 120 | 213 | 40 | 225 | 94 |

| PA-7XXX | 31 | 79 | 120 | 200 | 40 | 228 | 98 |

| PA-8XXX | 35.5 | 90 | 100 | 182 | 42 | 178 | 78 |

| PA-8.5XXX | 38 | 97 | 100 | 163 | 38 | 190 | 84 |

| PA-9XXX | 41 | 104 | 90 | 154 | 40 | 170 | 60 |

| PA-9.5XXX | 43 | 109 | 90 | 143 | 38 | 175 | 63 |

| PA-10XXX | 47 | 117 | 80 | 135 | 39 | 145 | 61 |

| PA-10.5XXX | 49 | 124 | 80 | 125 | 37 | 146 | 64 |

| PA-11XXX | 50 | 130 | 80 | 115 | 36 | 147 | 65 |

| PA-12XXX | 55 | 140 | 70 | 112 | 38 | 130 | 48 |

| PA-12.5XXX | 57 | 145 | 70 | 105 | 36 | 132 | 50 |

| PA-13XXX | 59 | 150 | 70 | 99 | 35 | 135 | 52 |

| PA-14XXX | 60 | 152 | 70 | 97 | 34 | 136 | 53 |

| PA-15XXX | 66 | 168 | 60 | 92 | 36 | 108 | 53 |

| PA-16XXX | 69 | 175 | 60 | 85 | 35 | 110 | 55 |

| PA-17XXX | 71 | 180 | 60 | 81 | 33 | 112 | 57 |

Images

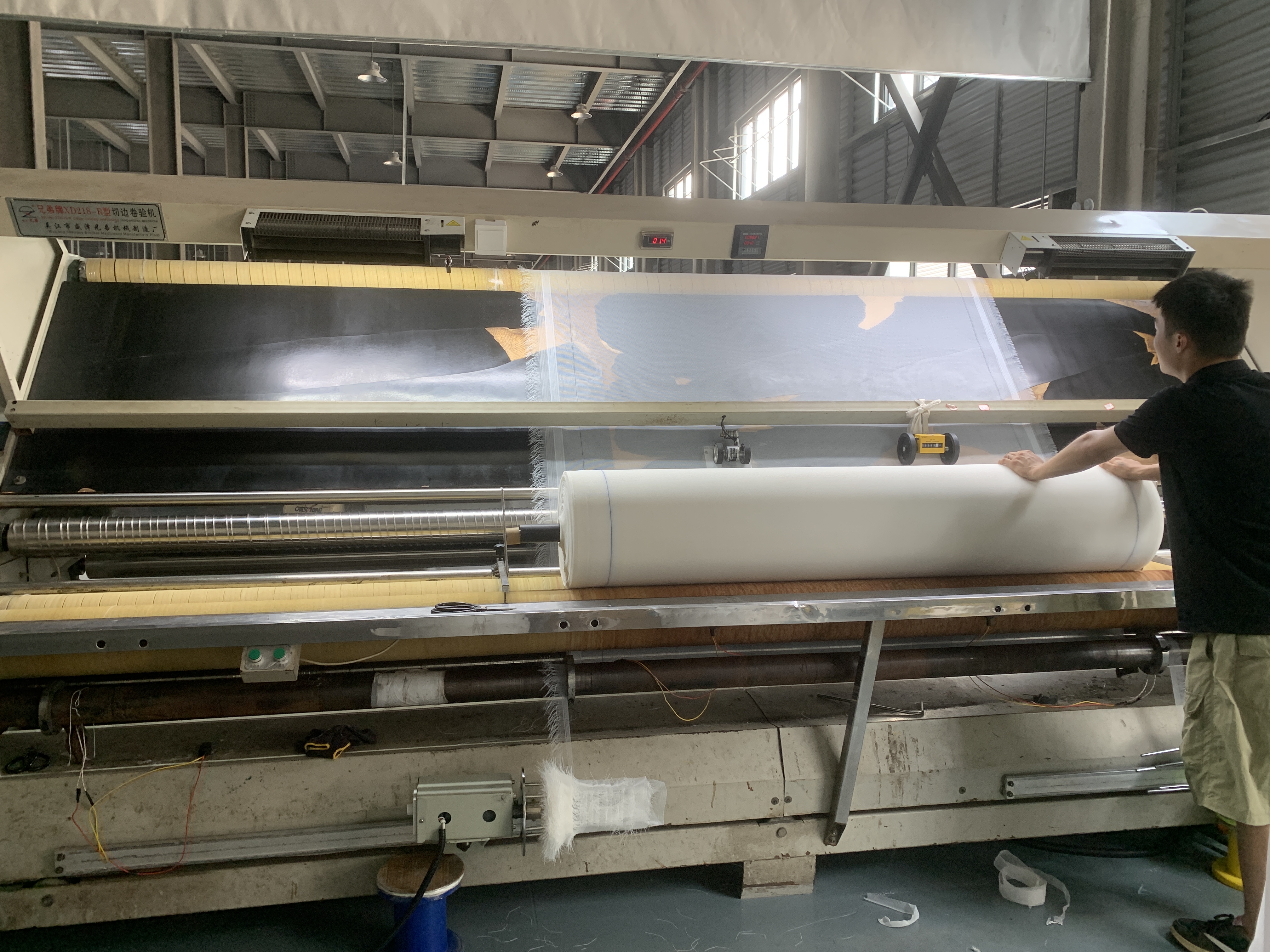

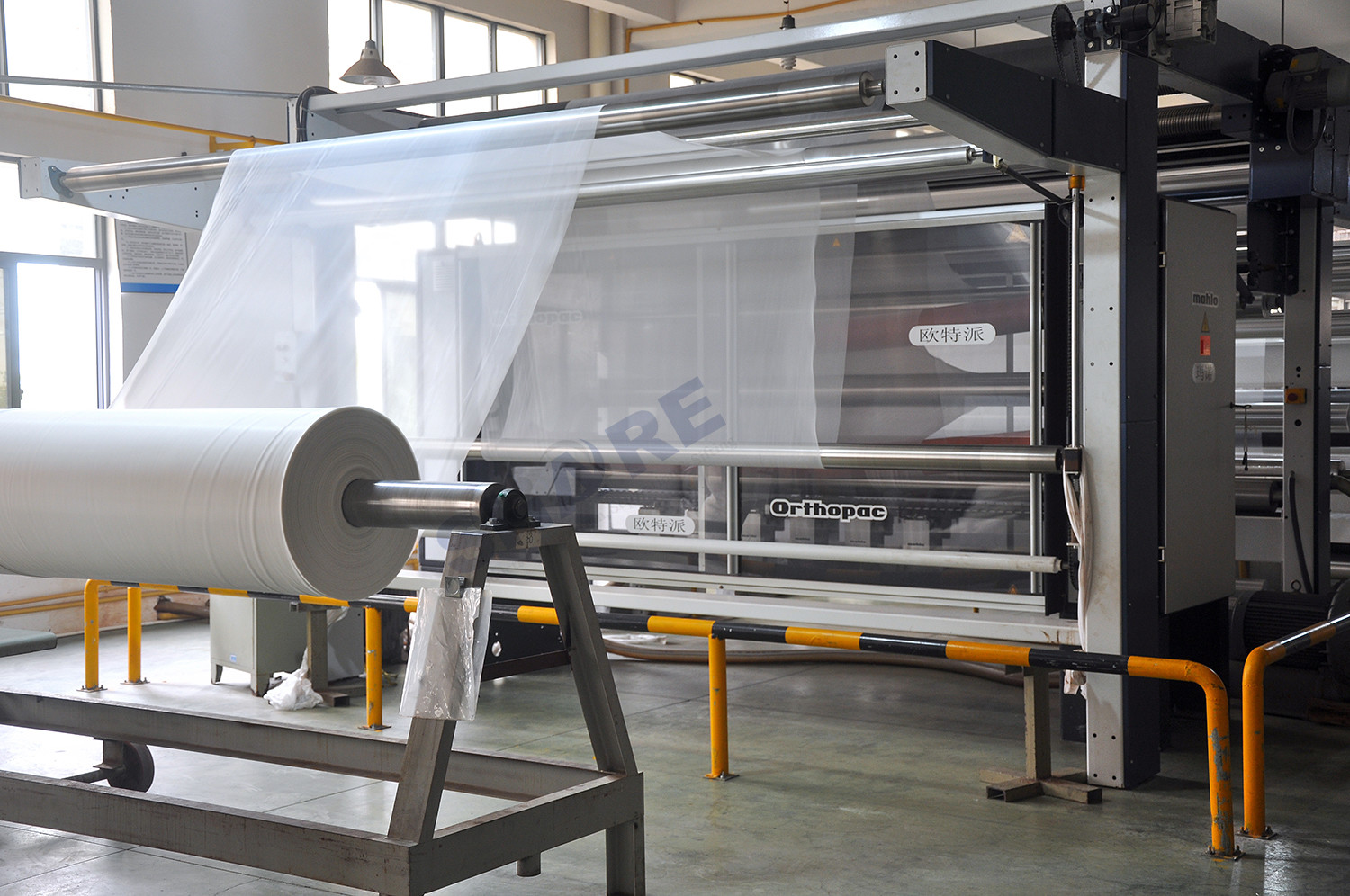

Production Process

Yarn

Monofilament

Weave

Plain Weave

Plain weave is made by crossing the warp and weft yarns with each other. Well-regulated and highly durable textile fabrics can be created as there are many points where the threads cross each other (structure points). It is also resistant to friction.

Since the warp and weft yarns appear on the front and rear surfaces of the textile uniformly, it is sometimes difficult to make a distinction between the front side and the rear side compared to other structures.

Product Procedure

Yarn→Raw yarn inspection→Warping arranging→Drawing in heddle→Drawing in reed→Weaving→Initial survey→Washing→Heat setting treatment→Physical properties inspection→Products inspection→Product→Fabricated mesh if needed→Plastic molded filters if needed

Mesh

SHARE precision filter mesh has smooth surface, great dimensional stability and strength than other material options, and tighter tolerance. It has different but precise mesh opening from 3um to 4400um. These allow for the different sized filter meshes to be used in different situations and for different purposes, such as home appliance, liquid filtration, dust collection or separation, dry and wet filter bags, sifting, milling, automotive, medical, food, pharmaceutical, molded filters and many more.

SHARE can further processed filter mesh into various forms of custom filters, such as filter pieces, shapes, ribbons, tubes, plastic filters by our state-of-the-art technologies of cutting, stitching, gluing, welding, laser cutting, molding and more, to fuifil customers and markets' demanding filtration and screening needs.

Company Profile

Established in 1983, Taizhou Share Filters Co., Ltd. offers a comprehensive range of woven monofilament filter mesh fabrics(nylon, polyester, polypropylene etc.) with micron ratings ranging from 3um to 4mm. We specialize in engineering woven fabrics into finished or partly finished products.

Our products are categorized into three classes.

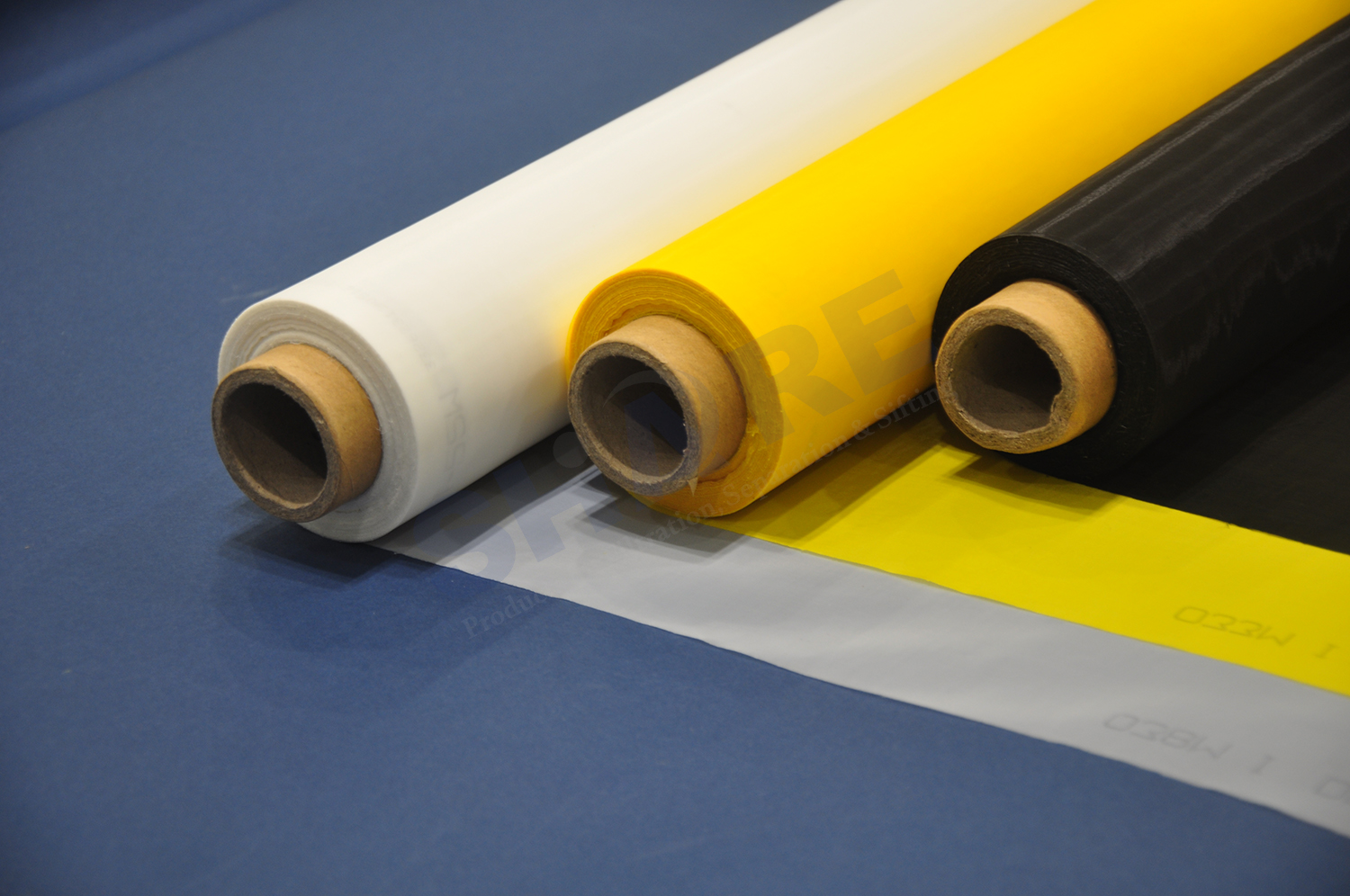

| Monofilament Mesh Rolls

|  |

| Discs, Tubes, Ribbons, Bags

|  |

| Plastic Molded Filters

|

Whether you want to improve the quality or reduce the cost of your existing filter component, plan a new filtration application, or need assistance with specifications and design validation, SHARE application specialists with decades of experience will help you create the best filter solution for your application.

Contact SHARE today for additional information and how we can help you with your specific filtration requirements.

Packaging & Shipping

1. Rolled on the paper core, 30-70m/roll, packed into PE bags, the product label is attached on the edge of each roll

2. 2-8 rolls per standard export carton

3. Put into PP woven bag to prevent damage during transportation

4. Package belt strengthen

For fabricated & molded filters:

1. Packed into sealed PE bags, 10m2 to 500m2/bag according to the actual size, double bagged and the product label is attached in the inner bag

2. Put into bigger PE bag and then standard export carton

3. Wrapped the outer carton with PE stretch film to prevent damage during transportation

4. Package belt strengthen if pallets are available

The label contains the following standard information:

item name, manufacturer, material, dimensions, manufacturing date, order number, batch number etc.

| Port to Port | Door to Door | |

| Express(DHL,UPS,FEDEX, EMS) | 1 - 5 days | |

| Air Freight | 1 - 5 days | 4 - 10 days |

| Sea Freight(FCL) | 15 - 30 days | 20 - 35 days |

| Sea Freight(LCL) | 15 - 30 days | 22 - 37 days |

FAQ

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your evaluation, which will be sent to you within 2 days. Please feel free to reach out to us for samples.

3. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need be confirmed, we will promptly notify you soon.

4. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically, it takes 5 to 15 working days for us to complete mass production once you have placed the order.

5. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and automated 3D image-inspection equipment, our production operators conduct self-inspections at every stage of the process. Additionally, we have spot inspections and final inspections carried out by our Quality Control (QC) team.

6. What's your largest advantage?

One of our core competencies is our excellent converting capabilities from yarn over weaving to converted items with professional technical team and quality guarantee and management for more than 30 years.

7. What kind of payment terms do you accept?

T/T and LC and more.

|

|

PA-XXX Series Screening Nylon PA6 Flour Milling Mesh 6XXX To 17XXX For Harder Types Of Wheat And Durum Images |